Offer asset tracking and fleet management

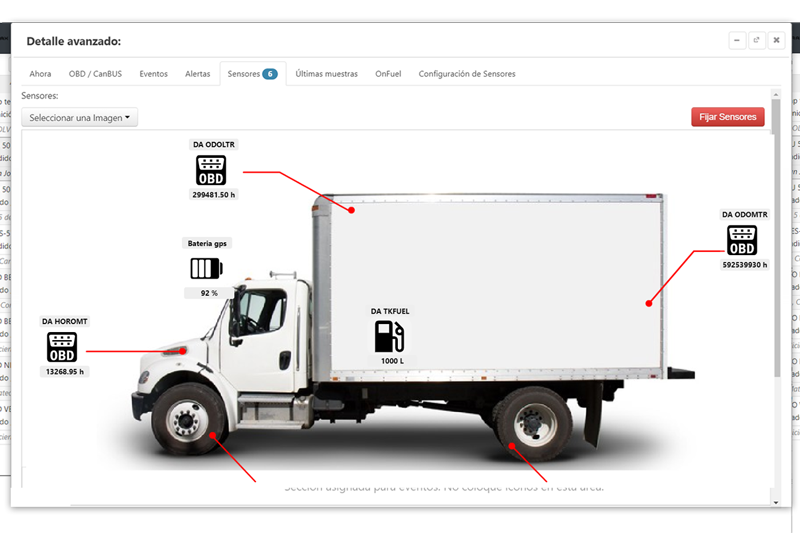

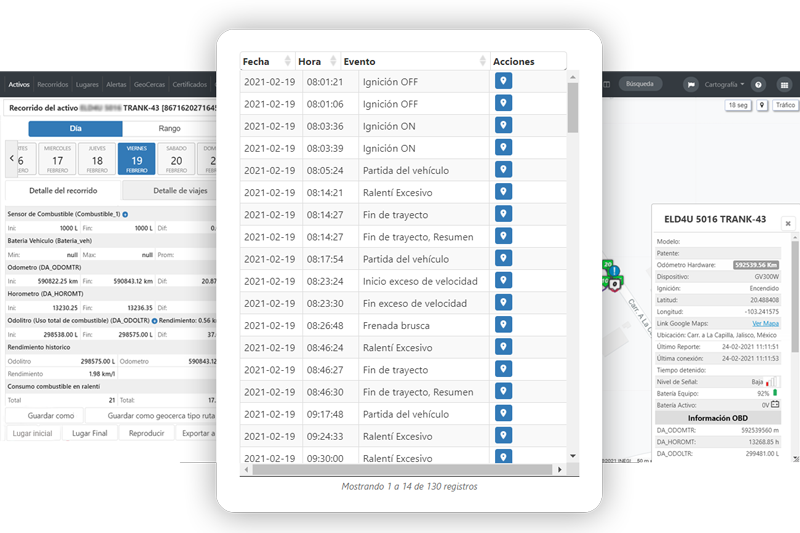

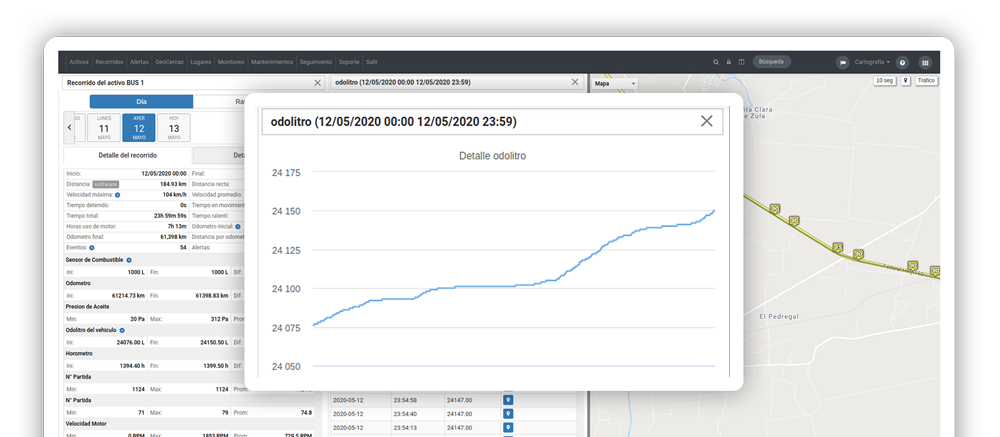

Three out of ten engines run on stolen fuel. How did Neotecnik decide to stop this problem?

Create flexible solutions for field personnel

Track and digitize sales force operations

Program and manage all fleet maintenance and generate budgets without the need for additional personnel

Discover the top 20 solutions and tools for tracking, security, and end customers

Discover how a virtual copilot in MDT terminals meets safety regulations and optimizes operations

How efficient cold chain control drastically reduces losses and damages to goods?

Offer tracking and task digitization for workers

One of the most critical activities in logistics management is asset control...

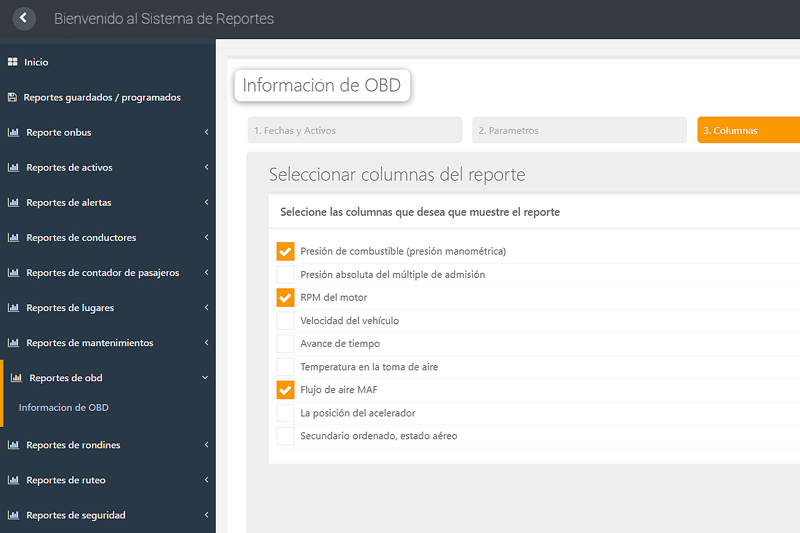

Partners is the platform for RedGPS clients and distributors from which they can manage all...

Three out of ten engines run on stolen fuel. How did Neotecnik decide to stop this problem?

With the right tools and guidance, migration represents an improvement in the service you provide to your customers and strengthens your position against the competition